Latex printing is an innovative technology that makes it possible to print on a wide variety of flexible and rigid media, from faux leather to banners, using eco-friendly and durable inks. This solution is revolutionising personalised textile design and visual communication thanks to its outstanding versatility and environmental credentials.

Imagine your designs printed on faux leather for a trendy handbag, an eye-catching event banner, or even a magnetic car wrap… With latex printing, your ideas come to life on substrates that were previously inaccessible. According to the Forrester – Q1 2025 State of B2B Events survey, 79% of event managers have made personalisation a top priority this year.

Summary

- Simple definition of latex printing

- How does this innovative technology work?

- The key benefits for your creative and communication projects

- Possible media: from faux leather to advertising banners

- Comparison: latex printing vs other technologies

- Inspiring applications for brands, agencies and hospitality

- Tissus Print expertise: 100% made in France latex printing

- FAQ

Simple definition of latex printing

Latex printing uses water-based inks enriched with polymer resins, offering an eco-friendly alternative to traditional solvent-based solutions. This environmentally conscious technology stands out thanks to its ability to adapt both to personalised textile projects and the visual communication needs of businesses.

Contrary to popular belief, latex printing does not contain natural latex but takes its name from the polymerisation process that binds pigments to the substrate. This innovative method delivers durable and resistant prints with no harmful emissions or unpleasant odours.

The competitive advantage of this technology lies in its exceptional versatility: it combines the quality requirements of the textile industry with the technical demands of professional signage, opening up new creative horizons.

How does this innovative technology work?

The latex printing process is sophisticated yet accessible. Water-based inks are heated during printing, activating the polymerisation of resins that encapsulate the coloured pigments. White ink can also be printed, ensuring full and even coverage on all types of substrates. This controlled chemical reaction guarantees optimal adhesion to the chosen medium.

The benefit to clients is immediate: the result is characterised by remarkable precision and vivid colours that retain their intensity over time. The absence of odour allows for immediate use both indoors and outdoors — a major advantage for projects destined for living and working environments.

The controlled temperature of the process also ensures excellent dimensional stability of the medium, preventing the distortions or shrinkage often observed with other printing techniques. This technical mastery translates into consistently professional finishes, project after project.

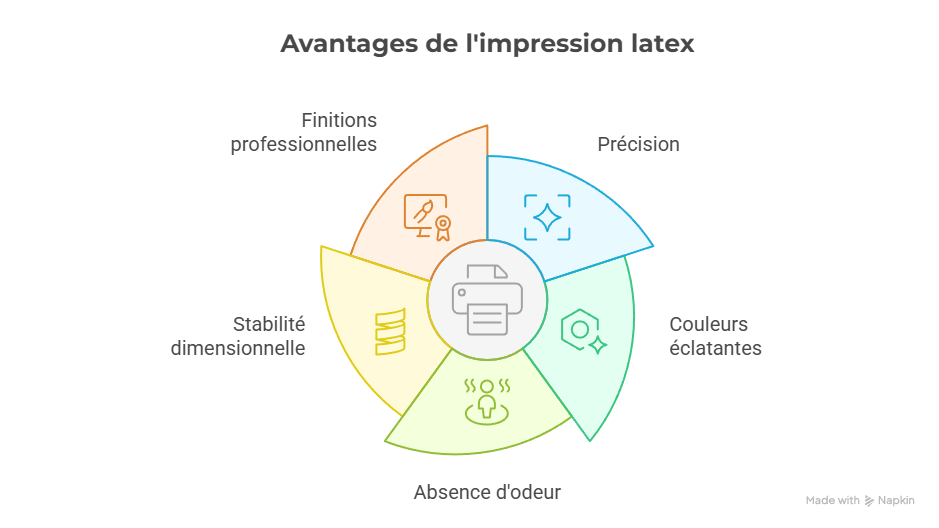

The key benefits for your creative and communication projects

Quality and durability

Latex printing offers outstanding resistance to common wear factors. Built-in UV protection preserves colour vibrancy for years, even in direct sunlight. Scratch resistance ensures a lasting “new” look, particularly valued for personalised faux leather bags.

The natural waterproofing of the polymerised coating effectively protects against humidity and splashes, making this solution ideal for demanding environments. The premium professional finish instantly enhances your creations, strengthening the brand image of your projects.

Environmental impact

Latex inks stand out for their total absence of harmful solvents, meeting growing demand for sustainable development. This makes them the preferred choice for hospitality and public spaces where indoor air quality is a priority.

The eco-certification of these inks enables businesses to align their creative projects with their CSR commitments, creating harmony between communication and values. The absence of toxic emissions during and after printing also safeguards the health of production teams.

Creative flexibility

The adaptability to both small and large runs democratises access to this premium technology. Whether you are producing a one-off prototype or a large-scale communication campaign, latex printing adapts to your volume and budget requirements.

Compatibility with a wide range of substrates — textiles, banners, faux leather, magnetic media — multiplies creative possibilities. This technical versatility frees the imagination of designers while respecting the operational constraints of professional projects.

Possible media for latex printing

The diversity of substrates compatible with latex printing opens up a whole new world of creative opportunities:

- Faux leather: creation of bespoke bags, promotional pouches and premium decorative coverings.

- Oilcloth: personalised tablecloths for events and durable decorative items.

- Flexible magnetic media: mobile advertising for vehicles and repositionable signage.

- Technical banners: large-format event communication, stand decoration and outdoor signage.

- Flexible textiles: personalised interior decoration and innovative textile signage.

For example, a fictional hotel-restaurant in the Var has chosen to customise its chair upholstery with printed faux leather reflecting its brand identity. This creative approach transforms standard furniture into unique decorative elements, enhancing the customer experience while controlling costs.

Faux leather: ideal for bags, pouches, chair and sofa coverings… See our complete guide to faux leather printing.

Similarly, an event agency in Toulon now uses customised latex-printed banners to decorate its stands. The print quality rivals traditional rigid media while retaining the ease of handling and storage inherent to flexible substrates.

Comparison: latex printing vs other technologies (UV, solvent)

| Technology | Print quality | Environmental impact | Substrates | Durability | Recommended use |

|---|---|---|---|---|---|

| Latex | High, vivid colours | Eco-friendly, odour-free | Very wide range | Excellent | Textile creation, visual communication, hospitality |

| UV | High, relief effects | Odour, chemical residues | Mainly rigid media | Excellent | Signage, rigid panels |

| Solvent | Good but limited | Low eco-performance | Vinyls, classic banners | Fair | Stickers, budget signage |

This objective comparison reveals why latex printing is gradually establishing itself as the benchmark for demanding projects. Its unique combination of quality, sustainability and versatility meets the contemporary expectations of professionals aware of environmental issues.

To learn more about the different digital printing technologies (DTF, DTG, sublimation, UV, latex…), check out our complete guide to personalised textile printing.

Inspiring applications for brands, agencies and hospitality

Creative brands use latex printing to develop distinctive accessory collections. Printing on faux leather allows for limited editions of handbags or original textile packaging that instantly stands out at the point of sale. This approach enhances brand image while keeping environmental impact under control.

Communication and event agencies integrate this technology into their premium services. Decorating stands with XXL latex-printed banners guarantees a professional, durable finish. Magnetic vehicle wraps offer a flexible alternative to traditional adhesives, simplifying maintenance and visual updates.

The hospitality and catering sector is discovering the benefits of latex personalisation. Personalised oilcloth tablecloths withstand intensive use while reinforcing the establishment’s identity. Printed decorative coverings transform communal areas into immersive communication spaces.

These real-world applications demonstrate how latex printing goes beyond technical execution to become a true driver of commercial differentiation and brand identity.

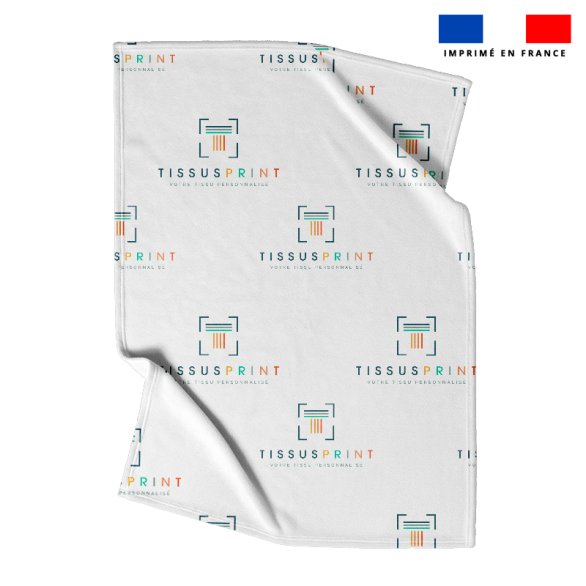

Tissus Print expertise: 100% made in France latex printing

Tissus Print has expanded its know-how to include latex printing from its workshops in the Var, guaranteeing complete control of the production chain. This local approach ensures rigorous quality control at every stage, from file preparation to product finishing.

In-house production guarantees reliable lead times and optimal responsiveness for urgent projects. Local proximity also facilitates technical exchanges and production adjustments, ensuring results that fully meet your expectations.

Our locally developed expertise continues to evolve through technological monitoring and client feedback. This commitment to continuous improvement positions Tissus Print as a leading player in personalised textile printing in the South of France.

Conclusion

Latex printing is establishing itself as a forward-looking solution that combines technical performance, environmental respect and limitless creativity. Its exceptional versatility meets the converging needs of personalised textiles and professional visual communication.

The tangible benefits — durability, print quality, odour-free, wide range of substrates — make it the preferred choice for demanding professionals. Its controlled environmental impact aligns your creative projects with today’s societal expectations.

Whether you are a brand seeking differentiation, an agency looking for technical excellence or a hotel wishing to customise its environment, latex printing opens up new creative opportunities.

Discover the potential of latex printing for your projects today and request your personalised quote from Tissus Print, French expert in textile printing and visual communication.

FAQ

What are the differences between latex printing and UV printing?

Latex printing uses solvent-free water-based inks, unlike UV printing which cures under ultraviolet light. Latex is more eco-friendly, odourless and compatible with a wider range of flexible substrates. UV excels on rigid media but generates emissions and requires appropriate ventilation.

Is latex printing suitable for outdoor use?

Absolutely. Latex printing offers excellent resistance to UV, water and weather changes. Polymerised inks retain their vibrancy for several years in direct outdoor exposure, making it an ideal solution for signage and outdoor event communication.

What are the most popular substrates for latex printing?

The most in-demand substrates include faux leather for personalised accessories, technical banners for events, oilcloth for hospitality and catering, and flexible magnetic media for mobile advertising. This diversity reflects the unique versatility of the technology.

Is latex printing durable over time?

Durability is a major advantage of latex printing. The polymerisation process creates built-in protection against UV, abrasion and moisture. Under normal use, prints retain their original quality for 3 to 5 years outdoors, and much longer indoors.

What are the best practices for preparing a file for latex printing?

Prepare your files in high resolution (300 DPI recommended), using RGB colour mode. Include a 3 mm bleed area and avoid placing important elements at the edges. Vector files (AI, EPS) ensure the best quality.

For a transparent background to preserve the natural colour of faux leather, use a TIFF file with transparency or a PNG file with preserved transparency.

0 commentaires