Table of Contents

- Introduction

- Design Preparation

- Printing on Transfer Paper

- Preparing the Fabric

- The Sublimation Printing Process

- Cooling and Finishing Touches

- Conclusion

Introduction

Sublimation printing is a cutting-edge and versatile printing technique that’s transforming the world of textile customization. At Tissus Print, we’re proud to use this professional-grade process to help you create high-quality, one-of-a-kind designs. In this guide, we’ll walk you through every stage—from preparing your artwork and textile to the sublimation process itself. Our goal is to give you all the insights you need to fully understand and master textile sublimation.

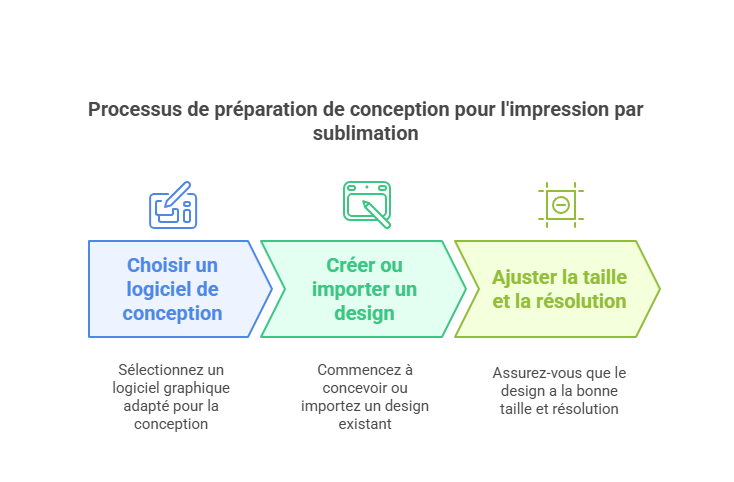

A. Design Preparation

Before beginning the sublimation printing process, the first crucial step is to carefully prepare your design. Choosing the right software ensures your artwork is the correct size and resolution for optimal print quality.

- Choosing your design software: Use reliable graphic design software like Adobe Photoshop, Illustrator, or Tissus Print’s online creation tools. These platforms offer advanced features ideal for bringing your vision to life.

- Creating or importing your artwork: Once you've selected your tool, start designing from scratch or import an existing design to adjust and customize it to your needs.

- Adjusting size and resolution: Ensure your design matches the dimensions of your fabric and is set at a high resolution for crisp, clear printing results.

Properly preparing your design sets the foundation for successful heat transfer sublimation printing and ensures a professional-quality finish.

B. Printing on Transfer Paper

Once your design is ready, the next step is to print it on sublimation transfer paper. This is a critical stage, as the quality of this print directly affects the final result on your fabric.

- Printer setup: Use a sublimation-specific printer and make sure it’s properly calibrated. Adjust settings such as print resolution and paper type to match the sublimation paper you’re using.

- Using sublimation inks: Fill your printer with sublimation inks, which are specially formulated to vaporize and bond with fabric fibers under heat, delivering vibrant and lasting color.

- Ensuring print quality: Make sure your design is printed sharply and cleanly. Poor print quality will impact the transfer results, so check your printer maintenance and use high-quality inks.

By following these steps, you can ensure your artwork is perfectly printed on transfer paper—an essential element for professional-grade sublimation printing.

C. Preparing the Fabric

Getting your fabric ready is a crucial step for achieving top-notch results in sublimation printing. First, it’s essential to choose the right type of fabric for your project. Polyester fabrics are ideal, as they absorb sublimation ink effectively and yield bold, long-lasting colors.

Once you've chosen the appropriate fabric, check if it needs any pretreatment. Some materials require this step to enhance ink absorption or add properties like flame-retardancy or stain resistance—features available in Tissus Print’s fabric range.

Finally, make sure your transfer paper is correctly aligned with the fabric. Precise positioning helps avoid misprints and ensures a clean, professional result.

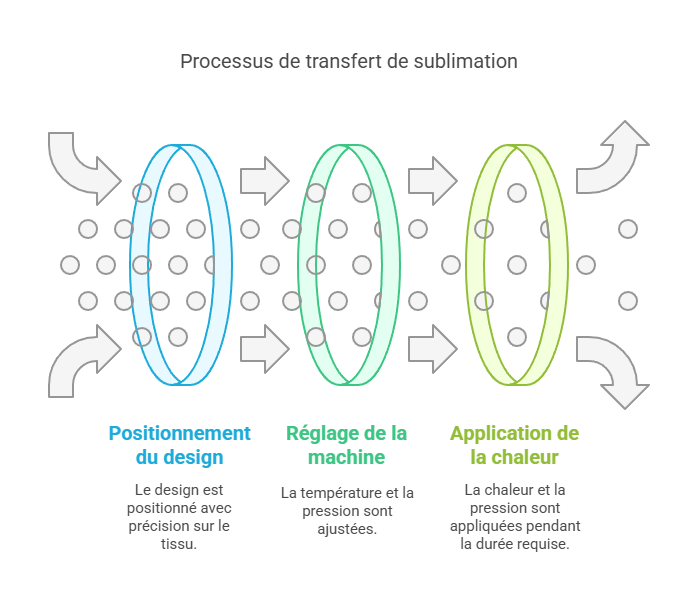

D. The Sublimation Printing Process

Now that your design and fabric are ready, it’s time for the sublimation process itself—transferring your design from paper to fabric using heat and pressure.

- Place your fabric and transfer paper into a heat press or calender press designed for sublimation. Make sure the design is perfectly positioned on the fabric.

- Set temperature and pressure according to your fabric and paper specifications. Follow the manufacturer’s guidelines to ensure optimal results.

- Apply heat and pressure for the recommended time. During this step, the ink sublimates—turning into gas—and bonds with the fabric fibers permanently.

By carefully following these steps, you’ll achieve vibrant, durable sublimation prints that stand up to washing and everyday wear.

E. Cooling and Finishing Touches

After the sublimation process, allow your fabric to cool down completely. This helps the design settle into the fibers for a long-lasting effect.

Once cooled, carefully remove the transfer paper to reveal your finished design. Handle with care to avoid damaging the print.

Next, inspect the final result to ensure it meets your expectations. Make minor adjustments if necessary to correct any small flaws.

Once everything looks great, your sublimation project is ready for use or display. Sublimated prints are wash-resistant and durable, giving your custom products a long and vibrant life.

Conclusion

To sum up, we hope this guide has given you a clear, step-by-step understanding of how sublimation printing works. From design to finishing, every stage plays a vital role in delivering high-quality thermal sublimation results.

| Stage | Required Equipment |

|---|---|

| Design Preparation |

|

| Printing on Transfer Paper |

|

| Preparing the Fabric |

|

| The Sublimation Process |

|

| Cooling and Finishing |

|

At Tissus Print, we’re proud to provide the tools, tips, and expert support you need to bring your sublimation printing projects to life. Feel free to reach out with any questions or for additional help. Thank you for choosing us for your textile printing needs—we can’t wait to see your custom creations! Learn more about the different fabric printing methods available at Tissus Print.

0 commentaires